Note: The content of this article comes from the online edition of "Steam Traction," a magazine covering steam engines. The writer is Carl B. Erwin, 106 S. Elm Street, Newkirk, Oklahoma 74647, who was a member of Company A, 1st Battalion, 20th Engineers.

We landed in France, November, 1917; and, after some delay caused by quarantine, got located on a tract of pine timber in the Dept. of Landes in Southwestern France. The word "Landes" in French means "waste land." In the old days it had been grown up in a kind of bushy shrub and was just about useless, except as a hide-out for the losers of a revolution. It was flat and sandy with small lakes and marshes; and the sand kept blowing and covering the strips of fertile soil along the small creeks.

This had changed when we were there. They told us that Napoleon originated the idea of planting it in pine timber, and a strip of country about twenty miles wide extending from a little south of Bordeaux almost to the Spanish border, was a nearly unbroken forest of pine.

Most of the trees had been tapped for sap to make turpentine and other products; but, only trees that showed signs of dying, and some older tracts had been cut. The French Government would not have allowed young, healthy timber to be cut, if it had not been so badly needed to carry on the war. A considerable number of people made a living operating the turpentine stills and small saw-mills; so, they would not allow large tracts to be cut, as that would have displaced whole neighborhoods.

The tract to which Company A was assigned consisted of about 1700 acres near the village of Mees, Landes. Company C was given a similar tract near Candale, Landes. The timber was very much the same; but Company C was close enough that the mill could be located on the standard gauge railroad; so, their production could be loaded directly into the standard gauge cars; while the Company A mill was located two miles farther back, which made it necessary for us to build a narrow gauge line to haul our lumber for shipment.

We set up camp in late December, 1917, but equipment was slow in arriving. We carried timber and built a barn for seventy head of horsers. The horses arrived, but no harness. The officers got out and bought a couple of little portable band sawmills and we got started cutting lumber. These mills were driven by English portable steam engines; one a Clayton and Shuttleworth and one Davey and Paxman. These engines were old but they ran well. Finally, about the middle of February, part of the machinery and blueprints arrived for an American mill, rated to cut twenty thousand feet per ten hours. The writer was given six men and assigned to the job of building. It was to be 90 feet long, 22 feet wide; built on posts six feet high, ten inches square, with street sill and over-lays of 10" x 10" timbers, which would make the mill floor nearly eight feet above ground. We went to work with a will, glad to be getting started. We bedded logs in the ground; cut perfect seats with foot-adzes for the footings of our posts, 36 of them, and were bragging about how level the tops were when some of the officers woke up and came out on the job. Bad news! The other parts of the mill had been lostmaybe sunk by submarines, or shipped to the wrong place; but, could not be found. So we were going to get a mill from the Canadian Lumber-Jacks.

You can well imagine the unprintable words that flew; but there was nothing to do except unroll the new blueprint and get started. The Canadian mill was to be 90 feet long, the same as the foundation we had built, but it was to be 26 feet wide insteadof 22 feet; and the posts were to be spaced at different intervals; so every pair of mud sills had to be moved, excepting those at the ends. As luck would have it, our mud sills were 26 feet long; so, by moving out to the end with our posts, they could be used. Of course our adze work all had to be done over; and, by this time, the logs were thoroughly covered with sand. Our adzes were all dull, and had to be ground with foot power. Electric motors didn't grow on bushes 59 years ago in Gascony. (The Department of Landes was part of the old province, called Gascony, before the French Revolution.)

We reset our mud-sills; cut the posts so the tops were level; got started with street sills and over-lay jointsa little farther along than we had been before; and now, you are not going to believe this, but it is true! The "Brass" decided to move the mill to another location, about three-quarters of a mile farther back in the woods. I believe I said earlier: Most of our working force had a low opinion of the "Brass."

We had cussed when we had to tear our work down before; but this time we wept. However, since there was nothing else to do, we salvaged all the material we could, hauled it to the new location, and went to work again.

This time it seemed our luck had changed. The Canadian Mill arrived about the time we were ready for it. The saw-rig had been designed by a Canadian officer, and built in England, but was very much the same as we had been accustomed to. The edger was of English design, but was not much different from the American edgers. It carried three saws and would handle lumber five inches thick. The live-roll case was gear-driven with ten steel rolls made from ten inch pipe, about thirty inches apart, making it 24 feet long. There were 30 eight inch steel idle rolls. This would extend nearly 100 feet if they were placed three feet apart. The cut-off saw swung from below, carried a thirty inch diameter saw that would cut a timber 8 x 10 inches. The power plant was the Twin Cylinder, 12 x 16" Robey Engine with Colonial Boiler that I described earlier.

By this time the operation had organized itself. All the commissioned officers but one had found other jobs. 1st Lieutenant Duncan P. Shaw from North Carolina knew something about saw-mills so he stayed on as Company Commander. Sergeant 1st Class J. W. (Bill) Puckett, an experienced construction man, was in charge of all camp and mill building. The writer, also a Sergeant 1st Class, was foreman in charge of installing the machinery in the mill.

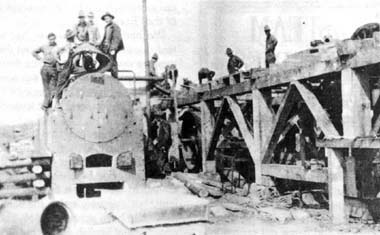

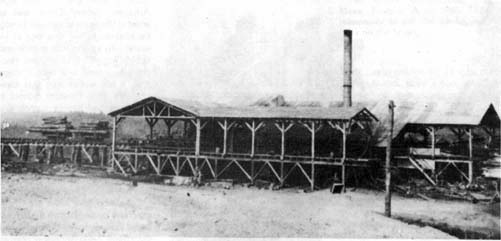

Mill under construction near Mees, France, April 1918. Using manpower to put the smoke stack base on the boiler.

The little portable band-mills were in operation cutting railway cross-ties and had rendered valuable service cutting the 8 x 8" timbers and lumber that we were using to build the large mill. Logging was getting started with Sergeant Frank J. Fitzgerald, an experienced logger from Port Angeles, Washington as woods foreman. The logs were being hauled on eight-wheeled wagons at this time, but they were expecting a gasoline-driven, 60 centimeter gauge locomotive to be used to haul logs from the woods.

Company A was loaded with skilled men. At least four: A saw-filer, two steam engine operators, and a mill foreman, were transferred and promoted to sergeants in other battalions that came later and were short of men who knew how to produce lumber.

The crew working on the mill had expanded by this time to about thirty men, and it was going up fast. Early in April we had the under-frame completed, the head rig set, the live rolls and cut-off saw belted up. Also, we had the haul-up rig working. The engine and boiler were set up and the smokestack was hoisted. The roofing had not arrived, but carpenters were cutting out the timbers for the shed.

The smoke stack goes up. There are three men on the boiler. The writer is the man in the middle. We were trying to get the first bolt in the flange. Sergeant Bill Buckett is standing on the corner of the mill building directing the operation.

Quite naturally, we were anxious to see the saws turn so we got up steam and started the Robey Engine to rolling. The belts all ran straight on the center of the pulleys and all the bearings ran cool.

They had shipped four new inserted tooth saws: Two, 52" diameter, and two, 56". All were 7 gauge at the center and 8 gauge at rim. The 52" had 50 teeth, and the 56" had 54. Both of the 56" saws were made by R. Hoe Co., whose saws are so well known, but one of the 52" saws was made in Canada. While we didn't know anything about the Canadian saw at the time, we found it to be equal to the Hoe in performance. The saws all seemed to be in perfect condition and were marked for 650 Rpm. I selected the 52" Hoe for the first run and, since I had been in charge of lining the track and mandrel, I appointed myself to saw the first log. Now, as everybody who has set up a saw-mill knows, this is a kind of tense moment. My mouth felt a bit dry, but as we brought the speed up to 650, the Hoe saw stood steady and true. I ran the carriage up and back on the track to see how the feed rig was going to work, then loaded a log and cut the first slab. The line was straight and we sawed the log into timber to build the shed. Ora W. Adkins of Columbia, Missouri, who was to be one of the regular sawyers, took the lever and sawed about a dozen logs. Everything ran well. We were especially well pleased with the way the Robey Engine performed. It carried the load so easily and the Pickering governor held the speed so regularly that you would have to have a good speed indicator to have detected any variation.

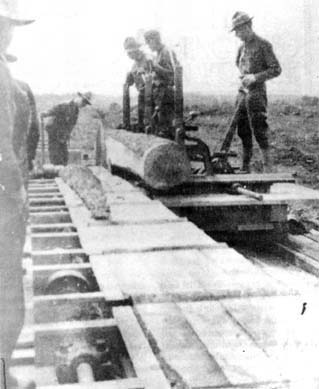

The first slab falls. Erwin is the man at the sawyer's lever. He squints down the line to see if it is true. It is good and the log is sawn without any adjustment of the saw and everybody was happy. Nearly ten million board-feet of lumber passed over those rollers by the time the Armistice was signed in November.

Readers familiar with saw mills will notice that the mill is left-hand. The Canadian mills that came from England were all left-hand. You know that the English drive on the left side of the road, so maybe they want their log carriage to be on the left. You know you can always tell an Englishman, but you can't tell him much.

After the trial run, we all got to work as fast as we could to get the mill completed. The carpenters finished the shed and we got the sawdust conveyors built and the edgers set up. In two or three days we had the belts all on and a full crew organized. The first day we cut over 200 logs and tallied thirteen thousand board feet of lumber.

The second day we cut nearly 400 logs, and tallied over twenty-two thousand feet of lumber. A crew was then organized for the night-shift and the mill went into operation for 120 hours per week. In a short time production was up to three-hundred-thousand feet per week. This required about 5,000 logs, so the loggers had to get busy. Fitzgerald and his men met the challenge quickly, and supplied the round stuff.

Company A had plenty of men who knew how to get out saw-logs; men who could pull a cross-cut and make it look easy. A man from Arkansas, named Davis, was an artist at filing a cross-cut saw. I would be anxious to bet that one of his saws, with a good man at each end, could "log-off" a chain saw. (Incidentally, I read in a reliable magazine, a few weeks ago, that some students at a Forestry School in Kentucky had beaten a chain-saw with a cross-cut in a "Log-Sawing" contest. It made me feel good to learn that we had some young men who could do something besides grow hair.)

When it came to getting logs to the mill, our loggers knew their stuff!

Folks who have never seen loading crews loading logs on the narrow gauge railway cars have missed something. Andy Anderson, born in Sweden, came to Montana as a boy, was the best logger and one of the most likeable men I ever knew. He was what they called a "top-loader," A loading crew consisted of five men and a team, or for small logs, one good horse. (When Andy was not busy loading logs, he was a semi-professional wrestler.) About 180 lbs. bone and muscle in "calked-boots", he was sure-footed as a tomcat, and no cat could catch a mouse quicker than Andy could snap his cant-hook into a log and bed it into place on the load; all this on top of a high load where one misstep would have meant at least a broken leg.

This crew could load 600 logs in 10 hours. If I could see Andy and his crew with their rhythm, grace and precision of movement, the best ballet dance that was ever staged could wait.

After the war, Andy returned to Idaho, where he became a successful as a contract logger. He and I used to call each other on the phone at Christmas time and talk about old times, but No More! He passed on to where good loggers go about one year ago. Truly his kind is an endangered species.

Mill after completion August, 1918.

Fitzgerald had another top-loading crew with a top-loader named Topel who could load almost as many logs as Andy's crew. These crews supplied the mill for the first month or two, but we made improvements in the mill and increased production; so, since they had plenty of good cant-hook men, two more loading crews were organized.

The mill was not cutting about 65,000 feet per day of two 10-hour shifts, and another problem arose. They had eight 4-wheel drive trucks to haul the lumber to the railroad about two miles away. They were having plenty of trouble. As they were designed for carrying ammunition they were needed at the front. This trouble ended when a steam locomotive built in Germany weighing about 7 tons, with four wheels, all drivers, arrived, it was not much for looks, but it could move 20,000 feet of lumber in five cars. We had to shut the saw-mill down for a few days, and take the crew to build a 60 centimeter gauge railroad to the French standard gauge line. The line we built was made with secondhand, 20 lbs. to the yard, steel. It was not a pretty track, but it carried the little train.

Sergeant John C. Henslee, Pineville, Louisiana, and Pfc. William P. Hillery, Akron, Ohio, with the little German locomotive. It wasn't much for looks, but it could move the lumber.

During the first month or more of operation, we had to use acetylene flare lights for the night-shift to work by. Servicing these was a messy job, and there was danger of burning the mill besides. This trouble ended when a fine, steam-driven electric generator arriveda Troy 7 x 9" steam engine, directly connected to a General Electric D.C. generator with an output of 125 volts, 80 amps. When we got this in operation and lights flashed on all over the camp and mill, we were as proud of it as Edison was of the Eighth Street Plant that ushered in the Age of Electricity. When you have passed a long, dark winter with no light excepting tallow candles, happiness consists of being able to turn on a light with the flip of a switch.

By this time we had acquirerd enough log cars to enable the log crews to leave enough loaded cars on the track leading into the mill to supply the night shift. The lumber hauling crew got hold of enough cars to take care of the full production from our lumber ramp to the railroad siding where it could be loaded directly onto the standard gauge. Yet this lumber haul continued to be a hard job. Sixteen men, eight for each shift, were required to transfer the lumber, and four men to operate the train, but it seemed to be the only way it could be done.

All along we were making improvements in the mill which increased the output. In the month of October, the last full month the mill ran, we cut 1,900,000 feet. Altogether, our little mill produced ten million feet of sawn lumber before closing down in November, immediately after the Armistice.

About the first of September, the writer was supposed to be promoted to a rank that is now called Warrant Officer, but the promotion got tangled up in red tape, and I only got to be "acting" Warrant Officer. This means I got the job but did not get the pay. A Warrant Officer is supposed to be an expert in some line in which the Army is engaged. The work in which I claimed expertise was the straightening and tensioning, and other work on circular saws. My job was "trouble shooting" for any of the five mills in the Dax District that had saw trouble or any kind of difficulty which their own men could not handle. The First Battalion had plenty of men who could recondition circular saws, but those that came later, although being composed of intelligent men, skilled in other lines, lacked the special skills needed for lumber production.

When the War ended in November, we all thought we would be packing our knapsacks and catching a boat for Hoboken in a few days, but how wrong we were! There were two million men in France and it had taken a year and a half to get us over there, so of course it was impossible to get back home very much faster. Any one would know it is not good for men to lie around in idleness, so various kinds of work, such as repairing roads and the like, were started, but for us there was something else.

Late in the summer a tract of pine consisting of about 30,000 acres, situated about 40 miles north of Mees where we were working, was burned. Every tree was killed, the bark charred; but the wood was not damaged. This timber was acquired jointly by the Americans and Canadian lumber regiments at a fraction of the cost of green timber.

At that time our High Command thought the War would continue into the next year, and we were all surprised when the Kaiser's Army collapsed in November, leaving the burned timber on our hands.

The French, with only a few small mills, would not be able to save much, as it would spoil in the summer, but they agreed to pay the Americans and Canadians the market price for all that we would cut. Our people wanted to be fair with the French and, naturally, everybody hated to see good lumber go to waste when it was needed badly. Since we had been bragging about how fast we could cut lumber, it was: "Why not get in there and show us?"

Three mills were to be built, twin rigs in each, making a total of six rigs of the size that we had been operating. Company A, or by this time the designation had been changed to "First Company," was to build one called the "East Mill." The "West Mill" was to be built by the Eleventh. I don't recall what Company was to build the "North Mill."

A Captain of Engineers named W. D. Starbird was in charge of the whole operation, and I mean He Was in Charge. During the summer of 1918, as new battalions had been arriving, Captain Starbird, with a detail of about 20 expert millwrights and construction men, had been building mills and starting them in operation for the new outfits that were often short of skilled lumbermen.

Later I was to become well acquainted with Captain Starbird and I found him to be one of the few officers in the regiment who really knew his job. He had a Master's degree in mechanical engineering and was Chief Installation Engineer for the P. B. Yates Woodworking Machinery Co., at that time the largest builders of woodworking machinery in the world.

This was the beginning of the operation called "The Burned Area," which most of the units of the Twentieth had a turn at helping clean up.

Fitzgerald, who had been logging foreman when we began work at Mees, and who had now been promoted to Lieutenant, with myself, still "Acting Warrant Officer," and Sergeant 1st Class George E. McKay from San Francisco, who had a Master's degree in engineering, were chosen to lead the advance into the black forest. We three were very close friends. This helped, but we wondered just what transgression we were being punished for. We were given an old FWD ammunition truck, ten men, two 16-foot tents, a few tools, a supply of hardtack and bacon, and told to get in there and build a new camp. This we proceeded to do, and as soon as we got tent floors with three foot walls ready more men were sent.

EAST MILL, Burned Area, near Pontenx Les Forges, Landes, France. This mill was built by First Company, 20th. Engrs. (formerly called Co. A First Battalion.) It began operation about the first of February, 1919, and cut four and one half million feet of lumber by the middle of June. The two other mills cut about the same making 13 million all together for the American mills and the Canadians about the same. This salvaged the burn and completed the work of the "Lumber Jack" Regiment.

A few days after we got started building our camp, Capt. Starbird sent a Warrant Officer, or as they were generally called, "Master Engineer," to commence building the mill. Master Engineer (I'll not give his name since he didn't turn out well and some of his descendants might read this) called on me for 12 good men. I responded by giving him the worst 12 I had. We needed every man who could drive a nail to work on the camp. I forgot to mention, it started raining the day we arrived in the black woods and continued to rain all winter, so we were much more interested in our camp than in the Master Engineer's mill. (Blank) was a fine construction man and he managed to get work done with the dozen useless guys. He seemed to be a fine fellow, and took it in good humor, but when he called for more men he asked if I couldn't send him some millwrights and carpenters. I responded by giving him the most worthless men I had, but this was as far as this shennanigan worked. He questioned these guys as to who were good men and they told him, so he came up with an order signed by Capt. Starbird calling for certain sergeants and corporals by name so I had to comply.

Master Engineer (Blank) knew how to build a mill. He soon had the main erected, and was getting started with the boilers and ovens. Possibly because of the frustrations and discomforts of the situationit rained almost continuouslywe were all black with soot from the charred timber, with plenty of cold water to use for washing and bathing. Altogether you couldn't say we were comfortable. All this was too much for Master Engineer (Blank). He got drunk, shot up the camp with a Springfield rifle, ran off, and they caught up with him in Paris.

Capt. Starbird chose a corporal named Goulasch to replace him as Superintendent. Starbird never paid any attention to rank or ratings. Another dictator was said to have preached the doctrine: "The tools to him who can use them." Starbird seemed to believe in that. Also, the powers in Washington had decreed that all ranks be "frozen," and no promotions were possible.

Cpl. Goulasch was a fine millwright and mechanic but proved to be a poor superintendent. He was what is called a "working foreman." This means a boss who will do all the work and let his men stand and watch. This is bad, when about 60 men are supposed to be at work.

By this time, we had the camp about finished, with mess hall, kitchen and supply room built of lumber, and tent floors enough to accommodate 500 men.

All of First Company (formerly called Company A, 1st Battalion) had been moved up from the old camp at Mees. Sergeant 1st Class George E. McKay, who was now logging superintendent, had surveyed and laid out the campsite and was building a 36-inch railway into the woods, getting ready to bring logs.

With the work on the mill lagging, Capt. Starbird was in a bind. Capt. Duncan P. Shaw (formerly 1st Lt.) who was in command of First Company, was now in the new camp. Capt. Starbird would hardly allow any of the other officers in the mill, but Capt. Shawbless his heart! He was one of the best friends I ever hadventured to speak to the great Captain, and told him that "Erwin could build the sawmill." To make a long story short, I got the joband how big I felt!

I put Cpl. Goulasch on a special job with four good men helping him, and we got along well and became good friends.

I have a history of the Twentieth Engineers that devotes a good many pages to describing the "horrible" conditions in the "Burned Area." The writers of this book talk a lot about "Slave Labor," men being marched to work in military formation and the like, and call Capt. Star-bird "the much anathematized Engineer Officer." I was too busy around the East Mill and camp to know much about what was going on in the other camps, but while we had a few complainers crying about wanting to go home, I could usually get them hushed-up by reminding them that about 200,000 of our men wouldn't be going home at all, and they should feel lucky. On the whole job, I recall only two instances of men refusing to work. I got them both back on the job without raising my voice, making any threats, or even getting mad. Lt. Fitzgerald, who was Camp Commander, never even heard of these incidents unless, perhaps, I happened to mention them and we had a "little laugh." When our men would complain about paddling around all day in "slicker suits" I would say: "We had to work last winter without these good suits." I'd also say: "We are lucky that this is just water and sand. What if it were black, sticky mud?"

Anyway, we got the East Mill completed, and it was a dandy. Two fine rigs built by McDonough, Eclaire, Wisconsin, set in right and left hand, so that the logs came in between and could be unloaded on the log decks. The whole plan was 80 feet wide by 84 feet long. Each mill was 24 feet wide by 84 feet long, with the boiler room 32 feet wide in between.

On the left hand rig, we used the 12" x 16" Twin Cylinder Robey Engine that we had used on our other job. On the right hand side, we had a new 14" x 18" side crank engine, built by Chandler & Taylor, Cincinnati, Ohio. The steam was furnished by the Robey "Colonial" boiler that we had used at Mees, with two open bottom fire-box type boilers of 50 H.P. each, set on a three-furnace "Dutch Oven," fired by sawdust conveyors.

We got the mill started late in January, 1919. Everything worked beautifully and I felt about as big as Capt. Starbird. In fact I heard that some of the men, behind my back, were calling me "Little Starbird." This pleased me. I had a high opinion of the Captain's ability.

Just before we got the mill started, the 25th Company, who had been running a mill in the Vosges Mountains, near the front, was sent to help run the operation. I continued as Superintendent. The other mills got started about the same time. As soon as all the mills were in operation, Capt. Starbird took off to his job with the Yates Company. He sent me a fine letter of recommendation on "Yates' Letterhead," which I have kept to this day.

We got the mill into good production, 20 hours per day, very quickly, cutting European type railroad cross-ties.

Another word about the 25th Company, who had been working in the Vosges Mountains near the front, and who had come to help operate the East Mill operation: I would particularly like to mention one of their sawyers and his crew. He was a French Canadian, a sergeant, but, they said, "He had been made sergeant seven times and 'busted' six times." His weakness: getting too much cognac and forgetting to come back to camp on Sunday night; but you should have seen him making logs into cross-ties. We had good sawyers, but none who had quite the "flair" and "style" of this man. The elegant gentleman who conducts the orchestra on the Lawrence Welk Show reminds me of him.

The crew that operates the head-rig in a mill of this type, consists of the sawyer who handles the motion of the carriage with one hand and bosses his crew by hand signals with the other, the "block-setter" and two "doggers" ride the carriage, and two cant-hook men roll the logs on the carriage and turn them. The carriage seldom stops except for an instant at the time it reverses. You may have heard old-time sawmillers talk about carriages so fast that you could play pitch on the "block-setters" coat tail! Well, this French-Canadian was almost that fast and his crew obeyed every crook of his fingers, all with precision and rhythm. If I could have a movie reel of Andy Anderson and his crew loading logs, and this sergeant (I don't remember his name) and his men sawing them, the Rockefeller family wouldn't have money enough to buy it. Oh, I might lend it to be copied.

Since First Company had been in France longer than any of the others except those of the old 10th Engineers, we were relieved on February 22 (easy to remember that date), 1919, by the 27th Company, and we went back to the old camp at Mees to prepare for the long trail to Hobo-ken. I have never known what units were used in operating the mills, but the History of the Twentieth says: "The job was finished in June, 1919, and the total cut by the Americans was: Thirteen Million Board Feet."

After we got back to our camp at Mees, about six miles from Dax, which is a little city of about 15,000 in which the headquarters of the first battalion and Dax District were located, General Pershing came down to visit us.

Our men had not been in military formation for over a year, and it was some trouble to get them in shape, but we managed to parade and pass in review. The General gave us a fine talk. He told us "we were a 'gutsy' bunch of guys, and while we had not had to face the enemy in battle, we had endured the back-breaking work, the cold, the heat, rain and mud, to furnish timber when it was needed, and he wanted us to know that our services were appreciated."

None of the units of the Twentieth were ever used in combat, but several of the mills were close enough to the front to be under long range artillery fire, and two men were killed. The greatest loss was suffered by our Sixth Battalion when the British troop ship "Tuscania" that was carrying them was torpedoed and sunk by a U-boat January 23, 1918. Ninety-one of our men failed to reach the shore. The 100th Aero Squadron was also on board and suffered heavy losses. Altogether about four hundred Americans were lost in this disaster when occurred off the Isle of Islay, near the coast of Scotland.

The delay caused the tract of timber intended for the Sixth to be given to the Seventh Battalion, and after the survivors of the Sixth regrouped, they were assigned to a job cutting timber for the British about 30 miles north of our operation at Mees. They built a couple of Canadian mills, like ours, and worked there for several months. During this time we became well-acquainted, and among the many things they told us about the sinking, one thing I especially remember was: "You may have heard that the Scots are stingy. Never believe it! We were picked up and landed on that little island, hungry and cold, many of us half drowned; and no clothes, excepting those we had on our backs. Those poor people gave us food and clothing that they really needed for themselves. So, 'Never tell us that the Scots are stingy!"

I was very much disappointed by failing to get the promotion to "Warrant Officer", but as a sort of consolation prize, several months after I got home in 1919, I received a citation for exceptionally meritorious service signed by "John J. Pershing." After all those years I prize this citation higher than I would have the promotion.

Nearly all of the mills were of two sizes. The larger units were rated to cut twenty-thousand board feet in ten hours. The smaller size was rated at ten-thousand. At different times, small portable mills obtained in France, were used. At the time the Armistice was signed, twenty of the twenty-thousand foot capacity mills were in operation; most of them running two 10-hour shifts per day. These mills were erected with the mill floors about 10 feet above ground, with the engine, line-shafts, belts and saw-dust conveyors below the floor. The smaller 10 thousand capacity rigs were set up "ground hog" style.

Of course Steam Engines turned the saws. The standard power plant for the large mills was a Houston, Stanwood and Gamble engine, 14 inch by 18 inch, rated to indicate 90 H.P. with 90 lbs. steam at the throttle. These were plain throttling governor engines with balanced valves. They were sturdy old workhorses; and, as for engine trouble, there wasn't any. The boiler plant consisted of: Two 48 inch dia. by 18 feet long, fire-box type b filers, nominal rating 50 H.P. each. Some of the mills, instead of two 50 H.P., had one 60 H.P. and one 40 H.P. boilers of the same type. These were all well built with "butt-strap" double riveted seams, good for 150 lbs. working pressure. However, as the war continued, machinery became harder to get; and, at least two, 20 thousand capacity mills were obtained from the Canadian Lumber-Jacks. These were similar to ours and the steam engines were built by Robey & Co., Lincoln, England. They were twin-cylinder, each cylinder 12 x 16 inches. The boilers were the horizontal return tubular type, 5 feet in diameter, 18 feet long. The furnace was a steel box, lined with fire-brick. The Robey Company called this outfit the "Colonial Boiler." They steamed well when fired by hand with sawdust; and, in one set-up, one of them was built on a "Dutch Oven" and fired by a sawdust conveyor.

The Robey engines were fine examples of the engine builder's art. Finely finished "engine turned" connecting rods made for good appearance, and finely balanced valves with eccentrics, made adjustable so as to use the expansion of the steam, made for efficiency. The eccentrics on the Robeys were made to work like the Russell reversing gear. They could not be reversed or the cut-off point changed by a lever while running; but, with the engine stopped, the cut-off points could be changed by loosening a couple of bolts, and sliding the outer part outward for a longer cut-off, or inward for a shorter. In case the bolts came loose, the eccentric could slip only to the central position. This would put the engine in the same position as with a reverse lever in the center notch. If it was desired to reverse the engine, it was necessary to remove the bolts. Then the eccentric could be slipped across the shaft, and the bolts put in other holes in the hub. Most steam engine men are familiar with the Russell and the old Rumely gears, and can understand how the slotted eccentric works.

The Robey engines were equipped with PICKERING governors, built in England under the Pickering Patent. They were exactly like the governors so well known in this country.

In describing these English engines, the writer does not want anybody to think that he is making them out to be better than those that came from the United States. The HOUSTON, STANWOOD & GAMBLE, the CHANDLER & TAYLOR, NAGLE and FARQUAR might not have been so finely finished as their English Cousins, but they kept the saws turning in most of the mills for two ten-hour shifts per day. Engine breakdowns were just about unheard of. Spare parts, such as cylinders and crankshafts, were shipped with many of the American engines, but it is doubtful if any were ever needed.

Most of the larger mills had steam-driven electric generators for electric lights. These consisted of a TROY vertical, 7" x 9" engine, directly-connected to a General Electric D.C. generator with a capacity of 110-125 volts, 80 Amps. D.C. current. These TROY engines had "automatic" governors and balanced valves. The crankcase was enclosed, and an oil pump circulated oil to all the bearings. It flowed from there through a filter in the base of the engine to be recirculated. These were sweet-running little outfits. "Automatic" engines are often seen at the steam engine shows; but most people think they merely have a different kind of governor. Actually, the "Automatic" operates in a radically different way from the throttling governor; and, in most cases, save one-third of the steam that the plain engine will use. On the "Automatic," the throttle is wide open so that there is full boiler pressure in the steam-chest, while the governor and valve gear are designed to control the speed by changing the TIMING of the closing of the admission; while, at the same time, holding the opening of the admission and "lead" at the beginning of the stroke. The Skinner Engine Company, Erie, Pennsylvania, took over the Troy Steam Engine Company, and was offering TROY Steam Engines for sale as late as 1961.

Most all of the larger mills used sawdust for boiler fuel; the slabs being shipped to the troops for firewood, the boilers that came from the States were all of the fire-box type with open bottoms. These were set on "dutch-oven" furnaces about six feet high. A chain conveyor carried the dust from the saws above the oven so that it fed by gravity into the fire. All the fireman had to do, was keep the fuel feed regulated and keep water in the boilers. The firing system worked well; usually plenty of steam; but, when the saws were all running all of the sawdust was not needed and part of it had to be hauled away. The Robey boilers that came from England were of the H-R-T type with steel fire-box settings. They also worked well on a Dutch Oven.

A large number of steam locomotives of various kinds and sizes were used for hauling logs and lumber. Most of the larger mills were located on the standard gauge French Railroads; but, some were not, and had to haul their output to the standard gauge for shipment.